Reliable NSN Parts, Delivered Worldwide

Supporting aviation, defense, and manufacturing industries with a vast inventory of quality NSN parts.

Experience fast, dependable service from a trusted supplier based in San Diego, CA.

Shop with Confidence

All products are certified (CofC)

Every product we offer comes with a Certificate of Conformance (CofC), guaranteeing that it meets all specified requirements and industry standards.

7 year record retention

We maintain a comprehensive 7-year record retention policy, ensuring that all documentation related to your orders and products is securely stored and readily accessible.

Counterfeit parts prevention system

We employ rigorous verification processes and partner with trusted manufacturers to prevent counterfeit parts from entering your supply chain, safeguarding the reliability and safety of your critical systems.

ASA (Aviation Suppliers Association) Member

As a proud member of the Aviation Suppliers Association (ASA), we adhere to the highest standards of quality and integrity in the aerospace industry. Our membership reflects our commitment to delivering trusted and reliable products that meet the rigorous demands of aviation professionals.

On-Time delivery record

With a proven track record of on-time deliveries, we ensure that your critical aerospace supplies arrive when you need them. Our commitment to punctuality reflects our dedication to supporting your operations without delays.

ITAR registered

As an ITAR-registered company, we are fully compliant with U.S. export control regulations, ensuring that our products meet the stringent requirements for international aerospace trade. This certification underscores our commitment to security, reliability, and regulatory excellence.

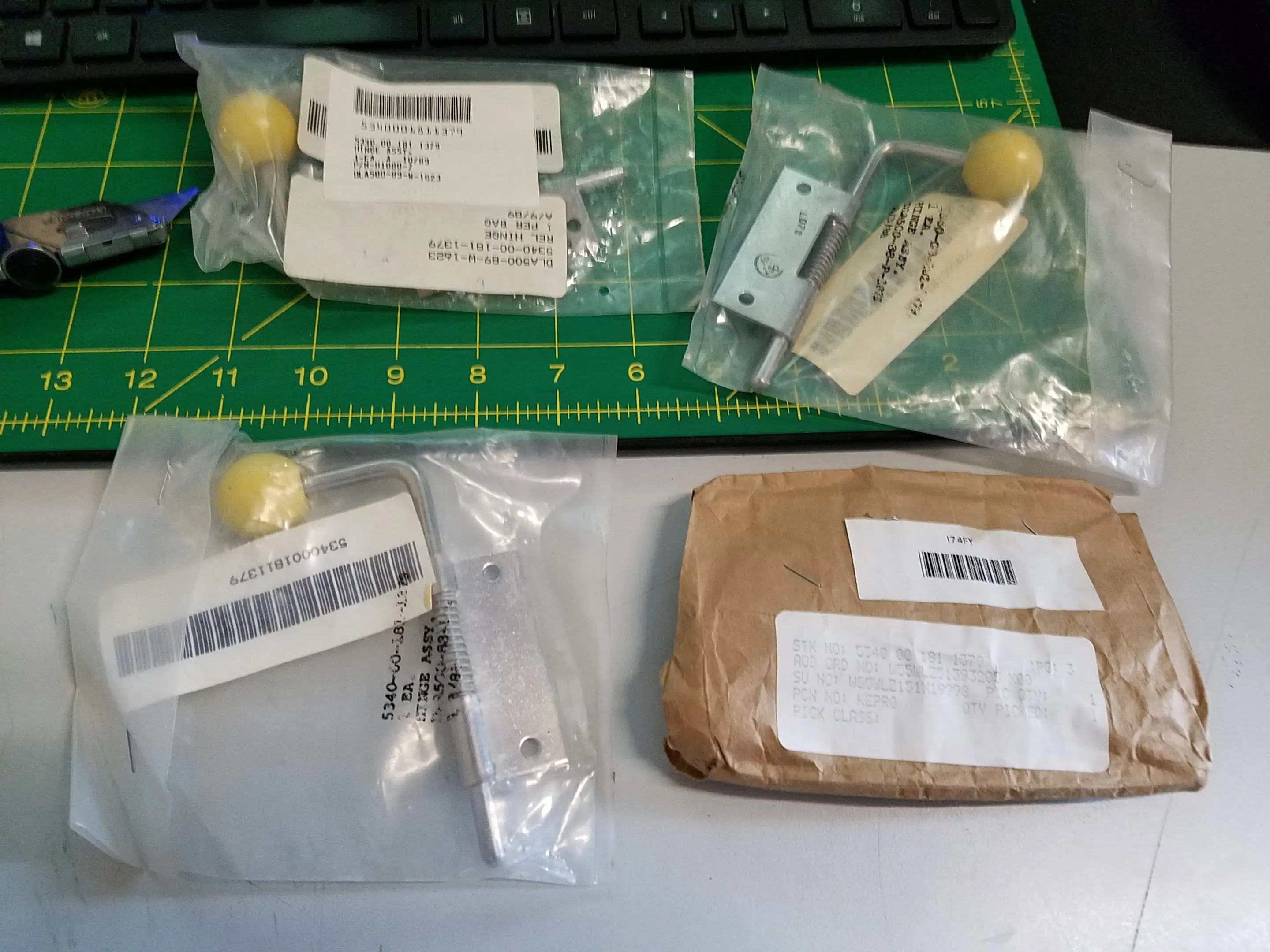

Hardware and Abrasives

We are commited to bringing you the products you need. We specialize in AN, MS, and NAS series hardware to

accommodate our aerospace and military customers. All of our hardware must pass quality control prior to being

shipped to the customer to ensure 100% quality on delivery.

Some of our hardware line includes:

→ Aeronautical Standard (AN) Series

→ National Aerospace Standards (NAS) Series

→ Military Standard (MS) Series

→ CherryMAX® Rivets

→ Hi-LOK™ Collars

→ Threaded Inserts

→ O-Rings

→ Gasket Materials

→ Spacers, Shims, Rings

→ Nuts & Washers

Product Categories:

→ Screws

→ Bolts

→ Studs

→ Nuts and Washers

→ Nails, Machine Keys and Pins

→ Rivets

→ Fastening Devices

→ O-Ring

→ Metal Screening

→ Commercial Hardware

→ Brackets

→ Weapon System Hardware

→ Abrasive Disks and Stones

→ Abrasive Materials

→ Packing and Gasket Materials

→ Knobs and Pointers

→ Coil, Flat, Leaf and Wire Springs

→ Bushings, Rings, Shims and Spacers

Electrical Components

Save time and money by ordering from nationalstocknumber.org where we stock and distribute thousands of electrical components every year. We are a trusted ITAR and DDTC approved supplier of general aviation, military, and truck platform electrical parts from resistors to circuit breakers to full assemblies.

Some of the electrical components we offer include:

→ Relays & Solenoids

→ Coils & Transformers

→ Electrical Wire

→ Circuit Breakers

→ Switches

→ Heat Shrink Tubing

Product Categories:

→ Resistor

→ Capacitors

→ Filters and Networks

→ Fuses, Arrestors, Absorbers and Protectors

→ Circuit Breakers

→ Switches

→ Electrical Connectors

→ Lugs, Terminals and Terminal Strips

→ Relays and Solenoids

→ Coils and Transformers

→ Oscillators and Piezoelectric Crystals

→ Electron Tubes and Associated Hardware

→ Semiconductor Devices and Associated Hardware

→ Electronic Microcircuits

→ Electronic Modules

→ Microphones and Speakers Handsets Headsets

→ Electrical Insulators and Insulating Materials

→ Electrical Hardware and Supplies

→ Electrical Contact Brushes and Electrodes

→ Optoelectronic Devices and Associated Hardware

→ Antennas, Waveguides and Related Equipment

→ Synchros and Resolvers

→ Cable, Cord and Wire Assemblies: Communication Equipment

→ Amplifiers

→ Electrical and Electronic Assemblies, Boards, Cards and Associated Hardware

→ Miscellaneous Electrical and Electronic Components

Paints, Sealers, and Adhesives

When it comes to providing sensitive shelf-life limited products nationalstocknumber.org is the best. We commit ourselves to providing accurate high quality products to our customers and understand the hurdles when dealing with HAZMAT and shelf life products. nationalstocknumber.org is a HAZMAT certified supplier with trained employees.

Some categories that we offer include:

→ Federal Standard Paints

→ Paint Brushes

→ Lacquer

→ Epoxy

→ Adhesives

→ Sealants

Product Categories:

Bearings and Bearing Balls

You need bearings? We've got bearings. We'll keep your operations moving and rolling smoothly. Reduce the friction of your work with the bearings you need, including:

Some categories that we offer include:

→ Bearing Balls

→ Mounted Bearings

→ Roller Bearings

→ Bearing Grease

→ Plain Bearings

→ Airframe Bearings

Product Categories:

Need Consumables?

Running low on essential supplies? Explore our extensive catalog of high-quality consumables designed to keep your operations on track.

Featured Parts

Products we have chosen to feature this week:

Machine Screw

NSN 5305-00-152-1000

Machine Screw

NSN 5305-00-152-1000

Flat Washer

NSN 5310-00-167-0807

Wood Screw

NSN 5305-00-180-1605

Rim Latch

NSN 5340-00-181-1379

Pneumatic System Compon Test Set

NSN 4920-00-192-1026

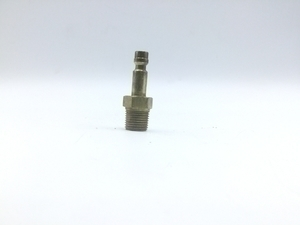

Tube Coupling Nut

NSN 4730-00-203-2662

Memorandum Book

NSN 7530-00-222-3521

Annular Ball Bearing

NSN 3110-00-227-3191

Circuit Card Assembly

NSN 5998-00-231-1998

Socket Head Cap Screw

NSN 5305-00-234-7812

Electrical Receptacle Connector

NSN 5935-00-250-7669

Hexagon Self-Locking Nut

NSN 5310-00-274-9408

Hexagon Self-Locking Nut

NSN 5310-00-274-9408

Electrical Conduit Adapter

NSN 5975-00-280-4313

Defense News

Navy, Air Force cleared to fly Ospreys after inspecting gears

5 days ago

The military is resuming flights of its tiltrotor V-22 Ospreys after ordering inspections of a gearbox to see which might be at risk of metal failure. (Mass Communication Specialist 3rd Class Amber Smalley/U.S. Navy)

Air Force secretary: Elon Musk ‘not a warfighter,’ needs to learn more

6 days ago

Outgoing Air Force Secretary Frank Kendall on Thursday downplayed Elon Musk’s recent pronouncements that crewed fighters are obsolete in the era of drones. (Anna Moneymaker/Getty Images)

No runways, no sorties: Chinese missiles threaten US airpower plans

1 week ago

Members of Marine Fighter Attack Squadron 242 clear new F-35B aircraft on Marine Corps Air Station Iwakuni, Japan, on May 9, 2021. (Lance Cpl. Bryant Rodriguez/U.S. Marine Corps)

New B-52 engines pass key design review, prepare for altitude tests

1 week ago

Rolls-Royce said the new engines planned for the B-52 Stratofortress will go into more intensive altitude testing in early 2025, now that it has passed its critical design review. (Staff Sgt. Lauren Cobin/U.S. Air Force)

Kurdish forces in Syria accidentally shot down US Reaper drone

1 week ago

Kurdish forces allied with the United States mistakenly thought an MQ-9 drone was an incoming threat and shot it down Monday. (Senior Airman Raya Feltner/U.S. Air Force)